1. What is Low-E glass?

Low-E glass is a common coated glass among home decoration glass, also called low-emissivity glass. It is divided into online Low-E and offline Low-E. Low-E glass can be used like a mirror to reflect far-infrared heat radiation in light.

So what is far-infrared heat radiation? For example, when you return home in the summer, all objects such as tables, chairs, and sofas are hot due to the sunlight, causing the temperature of the entire room to increase. This phenomenon is called far-infrared heat radiation. If Low-E glass is used in the window configuration, when the far-infrared heat radiation on the optical fiber strikes the glass, Low-E will reflect the heat radiation out.

In winter, because heat comes from indoors, it will be reflected into the room when the heat radiates to the window glass. Such a function can make the interior warm inwinter and cool in summer. This is low-E glass.

2. What is the difference between online Low-E and offline Low-E?

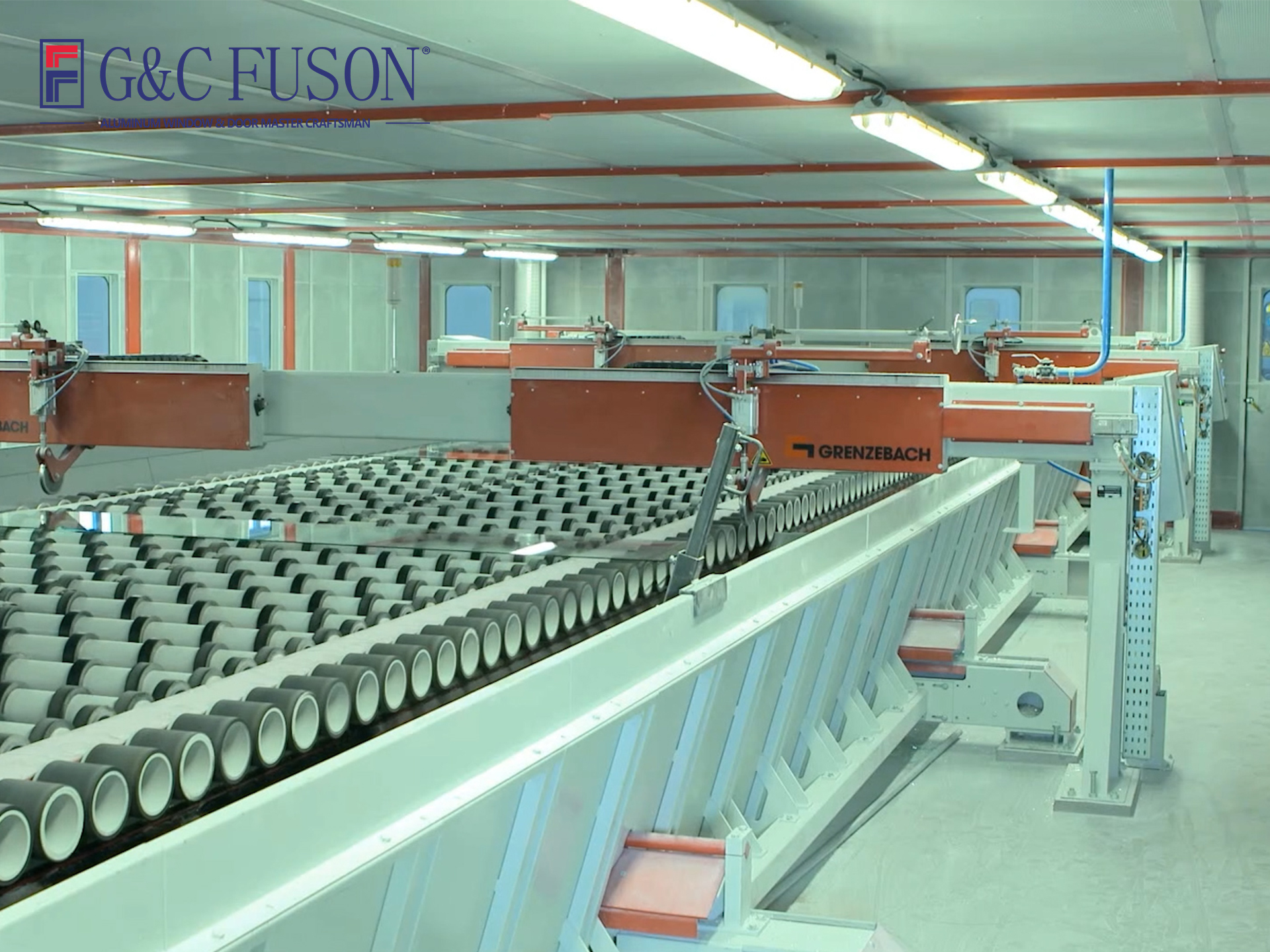

This refers to the two production processes of Low-E glass production, the online Low-E coating is completed at one time on the float line, while the offline Low-E glass leaves the float line and is completed separately on another line called a vacuum cathode magnetron sputtering line.

The thermal insulation performance of offline Low-E glass will be better, and there are more available colors, but the cost will be higher. It requires manufacturers to purchase additional coating lines, and the insulating glass must be made within two days. Online Low-E glass costs are low and can be used as a single piece, but there are fewer optional colors and the thermal insulation performance will be worse.

3. Which side of the insulating glass should the Low-E silver layer be plated on?

The film layer of Low-E glass is very easy to oxidize and can generally only be exposed to the air for a few hours. The coating layer is more likely to be scratched during the production and processing process. This is also an important process for the acceptance of Low-E glass doors and windows, therefore, it can only be plated on the inside of insulating glass.

Insulated glass takes two layers of glass as an example. It has four sides, 1234 from outdoor to indoor. The film layer should be placed on the inner surface of the glass, which is position 2 or 3 in the picture. But should it be placed at position 2 or 3? This has something to do with North and South.

Through the following pictures, we can see it intuitively. If you are in the southern region where heat insulation is important, the low-E film layer should be placed in position 2 to prevent more heat from entering the room. If you are in the northern region where insulation is important, Low-E should be placed in position 3 to block more heat loss.

Please contact us if you are interested in:

➡️Learning more about our product,

➡️Being a partner or reseller/distributor in your region,

➡️Placing an order,

➡️Requesting a sample for testing.

E-mail:export@fusonwindoor.com

Mobile:0086 180 281 569 60

Phone/Fax:0086 757 8572 0682

Our team is committed to working tirelessly to provide the value our clients and distributors deserve and the great experience they expect from us.