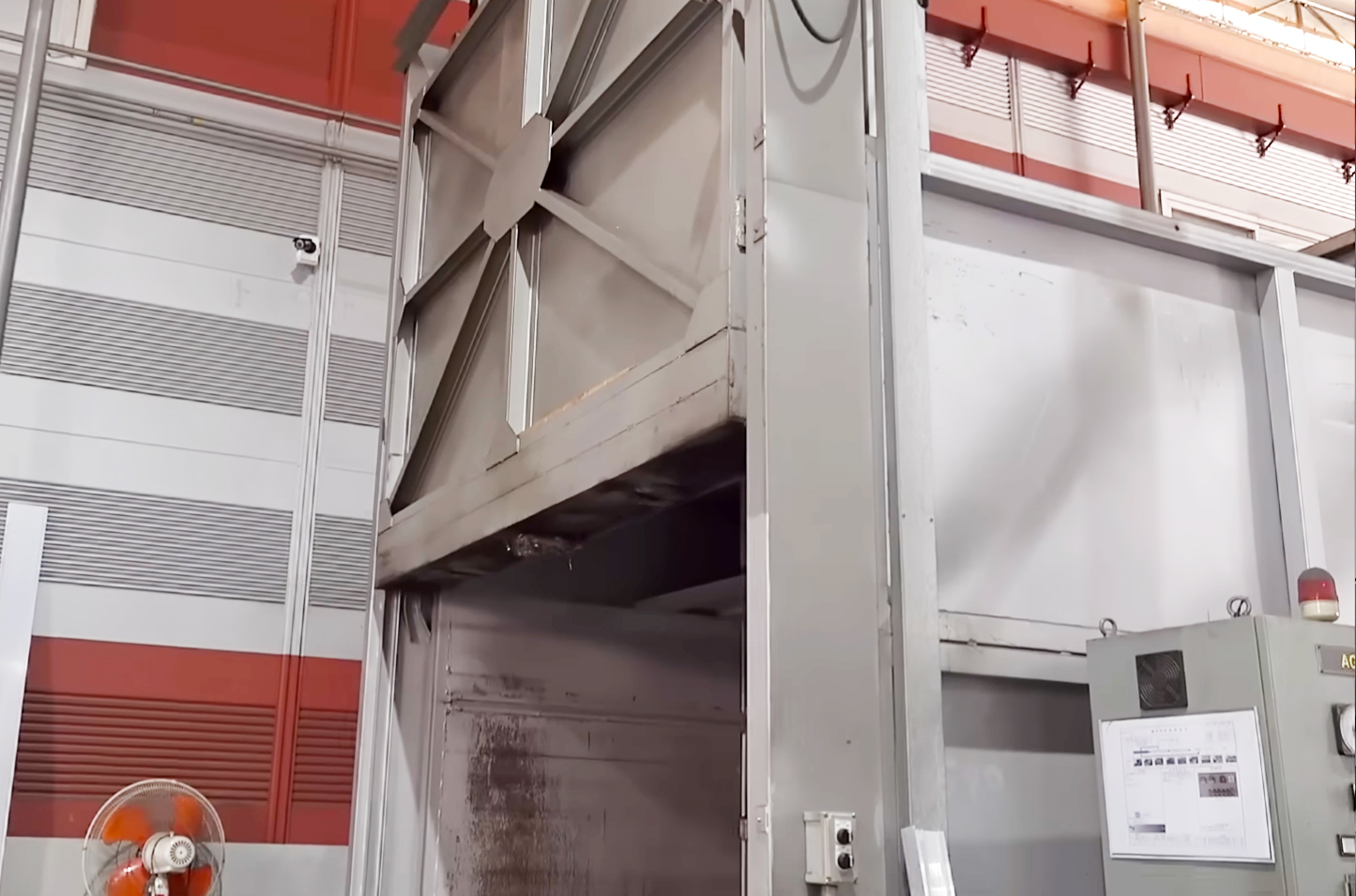

sandblasting + oxidation treatment process

Sandblasting cleans and roughens the surface of aluminum profiles by spraying fine abrasives at high speed. This treatment can not only remove impurities, oxide layers, and residual grease on the surface of the profile but also provide a better adhesion basis for subsequent oxidation treatments.

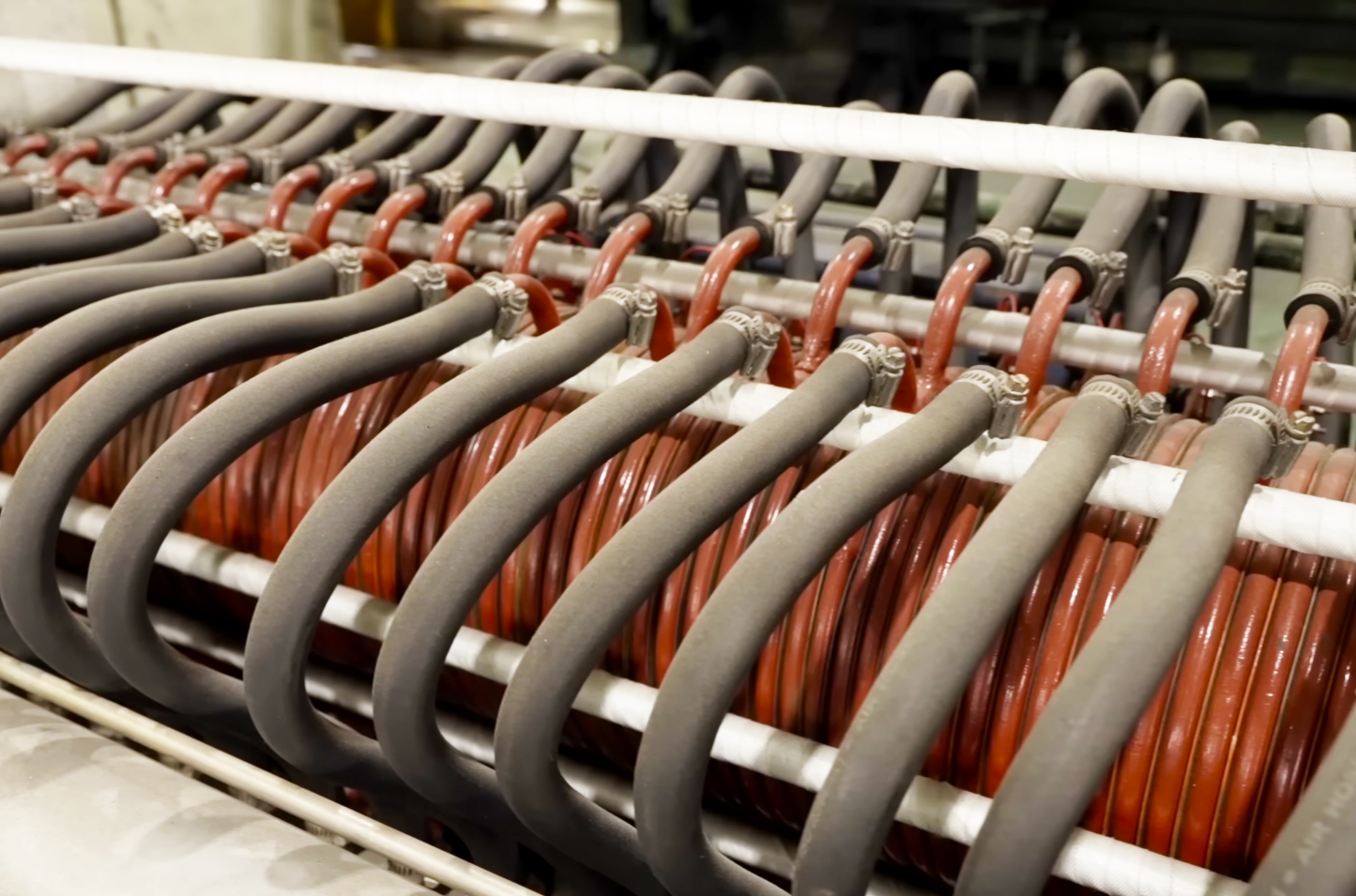

What follows is an oxidation treatment, an electrochemical process that prevents further oxidation of the aluminum by forming a dense oxide film on the surface. The oxide film is extremely hard and can greatly improve the corrosion resistance, wear resistance, and weather resistance of aluminum profiles, which is crucial for the long-term use of doors and windows.